History of Quilting

History of Quilting

Quilting is defined by the Encyclopedia Britannica as the "process of stitching together two layers of fabric, usually with a soft, thick substance placed between them. Quilting is a very practical item where the layer of wool, cotton, or other stuffing provides insulation; the stitching keeps the stuffing evenly distributed and also provides opportunity for artistic expression in both design and execution." This pretty much sums everything up EXCEPT it doesn't give you the history that led up to the invention of quilting.

The interesting thing is that quilting isn't American. It isn't even European. In China, India, early Egypt, Persia (modern day Iran), the Middle East, all used quilted fabric as clothing. Piecing patchwork was practiced during the early Egyptian times.

Textiles came about as the result of ancient handicrafts. But before we can talk about fabrics we need to talk about how fabrics are made.

Fabrics are made from threads. Thread is made of such fibers as cotton, flax, wool, silk, or other textile material. Since we are discussing the history of quilting we will be discussing the history of thread. This is where things might get a little difficult. There are literally 20,000 years of history. A lot of that history is about thread.

The earliest textiles may have been were nets, which were used for fishing, produced from one thread and employing a single repeated movement to form loops, and basketry, the interlacing of flexible reeds, cane, or other suitable materials. The production of nets, also called limited thread work, has been practiced by many peoples, particularly in Africa and Peru. Later rope was developed to catch deer by the antlers.

Examples of prehistoric textiles are extremely rare because of the perishability of fabrics. The dry, dark and sterile sands of the desert have provided some of the best conditions for the survival of textile items. One of the reasons why we will be looking at the textiles of Egypt is because so many of the textiles that have survived so many years is because they were protect by the dry conditions. South America also has the same conditions in Peru. There the climate is very dry especially at the higher elevations in the dry coastal areas of northern Peru.

Not only does dryness preserve textiles, but low temperatures proves to be a means of conservation. Mongolia and the Central Asian Steppes have uncovered important textile finds that date back to the 5th Century BC.

In the peat bogs of Scandinavia many textiles have been recovered. The interesting thing about the peat bogs is that entire garments have been discovered thus allowing researchers to examine how the clothing was made and worn.

Flax was the commonest ancient plant fiber. Hemp, rush, palm and papyrus were also used. Papyrus requires a good water supply and settled communities for its cultivation. Seeds of domesticated flax found with spindle whorls together on the same site are indicative of textile activity. These have been found in Syria in Ramad (6000 BC)., Samarran villages in northern Iraq (at Tel-es-Sawan and Choga Mami) (5000 BC).

The domestication of sheep, goats and dogs dates from 9000 BC in the uplands of Zam Chem Shanidar from 7000 BC at Jarmo in the Zagros Mountains of north west Iran, and Palestine (Israel) and south Turkey from the 7000 to 6,000 BC. Sheep rearing became major industry in Sumeria between 3,500 to 3,000 BC, by which time both hairy and wooly sheep were known.

Ur's principal export became wool and the Law of Hammurabi (1,800 BC) lists wool as an export from Babylon.

Sheep were also kept at Bougras in Syria from 6,000 BC and in Jordan and Palestine (Israel) from 3,000 BC often simultaneously with flax cultivation in mixed farming economies, and by pastoral nomads, including the Old Testament Jewish tribes, whose sheep provided wool for tents from time immemorial.

The title of "earliest textile" has recently shifted from Egypt to Anatolia (modern day Turkey), with Egypt and Israel close contenders. James Mallet's dig at the Neolithic village of Catal Huyuk in southern Turkey dating from 6,000 BC, exposed fine-spun and plied-thread, plain weave tabby cloths and garments, some of the tabby designs showing signs of being darned.

A burial couch found at Gordion in ancient Phrygia and dated to 8,000 BC was covered by some twenty layers of linen and wool cloth, together with traces of Tyrian purple cloth and fragments of hemp and mohair.

Israeli excavations reveal that the deserts of Israel provide ideal conditions for the preservation of fibers. Finds from the Neolithic Hemal Cave in the Judean desert dating from 7160 to 6150 BC including rope, netting matting, spun and plied thread, chiefly flax, and tabby woven cloth, including a blue-dyed textile with shell and bead decoration.

Textiles found in Israel obey the Jewish Law (Shaatnez), prohibiting the mixing of animal and vegetable fibers, but otherwise are similar to textiles elsewhere. In the Cave of Letters, 132 BC-AD 35, indigo-and purple -dyed yarns, white wool tent yarn, plain and striped tabbies, garments and linen scroll-wrappers were found. At the Masada, destroyed by the Romans in AD 273, the baskets and mats of the Zealots who died there were preserved with household cloths, tapestry, clothing and sandals.

I feel that we must talk a little about Shaatnez (the Israeli practice of not mixing different yarns). Initially, the practice of not mixing different yarns came from the need to be ritually pure, IE, not to intermingle the practices of what other races of people also living in the Middle East were also doing. The other people's living in the Middle east were also practicing such acts as infanticide, infant immolation, etc. The people of Israel not wishing to live like their contemporaries abstained from these acts. The concept came from not mixing their lives with their contemporaries. Thus, the Jews did not mix their yarns. Doing so would be living as their contemporaries did, IE, sinfully.

To this day there are Orthodox members who refuse to wear a garment made from mixed threads. They will not wear poly cotton. They will wear either one, but not mixed.

3300 BC The ICEMAN also spelled ICE MAN, also called ÖTZI, the oldest mummified human body ever found intact. It was found by a German tourist, Helmut Simon, on the Similaun Glacier in the Tirolean Ötztal Alps, on the Italian-Austrian border, on Sept. 19, 1991. Radiocarbon-dated to 3300 BC, the body is that of a man aged 25 to 35 who had been about 1.6 m (5 feet 2 inches) tall and had weighed about 50 kg (110 pounds). He apparently fell victim to exposure or exhaustion while crossing the Alps and died of freezing. The small rocky hollow in which he lay down to die was soon covered (and protected) by glacial ice that happened to be melting 5,300 years later when his body was discovered by modern humans. His nickname, Ötzi, stems from the Ötztal Alps, where he was found.

The Iceman's body showed no signs of disease, though he had a broken nose and several recently fractured ribs. His few remaining scalp hairs provide the earliest archaeological evidence of haircutting, and short blue lines on his skin (lower spine, left leg, and right ankle) have been variously interpreted as the earliest known tattoos or as scars remaining from a Neolithic therapeutic procedure. The various clothes and accouterments found with him are truly remarkable, since they formed the gear of a Neolithic traveler. The Iceman's basic piece of clothing was an unlined fur robe stitched together from pieces of ibex, chamois, and deer skin. A woven grass cape and a furry cap provided additional protection from the cold, and he wore shoes made of leather and stuffed with grass. The Iceman was equipped with a small copper-bladed ax and a flint dagger, both with wooden handles; 14 arrows made of viburnum and dogwood, two of which had flint points and feathers; a fur arrow quiver and a bow made of yew; a grass net that may have served as a sack; a leather pouch; and a U-shaped wooden frame that apparently served as a backpack to carry this gear. His scant food supply consisted of a sloeberry, mushrooms, and a few gnawed Ibex bones.

EARLY TRADE

Archeological evidence shows that trade was established as early as the Neolithic period in 7,000 BC. Wool and cloth were important trade goods in the east-West trade. Maritime trade between south Mesopotamian cities and the Indus Valley is documented by tablets which refer to trade with 'Dilmun' (Bahrain), and 'Makan' (probably Oman). Urs textile goods were exchanged for raw goods. A tablet of 2,026 BC records a loan of Ur's Temple of Nanna to a merchant of "sixty talents of wool, seventy garments and 180 skeins for buying copper from Makan." Ur also traded up river to Babylon and Mari in north Syria.

The earliest evidence of weaving, closely related to basketry, dates from Neolithic cultures of about 5000 BC. Weaving apparently preceded spinning of yarn; woven fabrics probably originated from basket weaving. Cotton, silk, wool, and flax fibers were used as textile materials in ancient Egypt; cotton was used in India by 3000 BC; and silk production is mentioned in Chinese chronicles dating to about the same period.

The reason that the Middle East was the area where cotton grew into use is because of the type of the cotton that grew there. The type of cotton that grows in the arid climates is known as pima cotton. Pima cotton is also known as Egyptian Cotton. Pima cotton has a longer more flexible staple fiber that regular cotton. The result is that the fabrics that were made were longer lasting, thicker, better quality and more importantly, more durable than the standard cotton staple that is grown in the other parts of the world.

It is believed by archeologists that the initial making of thread was done by separating the inner layer of tree bark from the outer layer. This resulted in the inner bark surviving the working as small pieces of very delicate threads. Far to delicate to be useful. The problem that had to be next faced was the delicateness of the thread. The thread was so delicate that it good for nothing by itself. What happened next took ingenuity and cunning: The person took several of the small strands and twisted the fibers together. This resulted in a much stronger piece of thread. This scenario occurred approximately 15,000 years ago. We know because one of the early fragments were found in a cave in France. It was discovered in a small lump of clay and it left its imprint on the clay. The thread had dissolved due to the dampness of the clay. BUT the imprint on the clay of the thread was still there.

Later threads were woven together by simply taking the fibers and rubbing them on the outside of the thigh. This was efficient as it only used one hand. If someone was in real need for additional threads (actually yarn) they could rub the threads on both thighs at the same time. But this only applies if you are making short, very short pieces of thread. If you are going be making longer pieces of thread, then you will need to keep adding to the threads as you form them.. You will be needing at least four hands. One to hold the thread, one to form the thread, one to keep rolling the thread and one to keep winding the thread as it is formed and added to the other threads. I am certain that it took to two people to begin the process of creating thread. However, this is an inefficient use of manpower when we keep in mind that the early settlers had a lot of things to do during the day to maintain their family. They had to hunt, gather food, etc. Grind whatever grain they used. All of this took time.

So what was eventually invented so that the person only needed two hands and not four? There were several inventions that came along...one was the spindle. A spindle is nothing more than a stick about a foot long. A twig would suffice. Especially if the bark has been removed. Removing the bark makes the stick smoother and the threads won't get caught on the twig as readily.

The person doing the thread making would attach the new thread to the tip of the tree limb. They would then turn the stick slowly at first. Turning the stick will cause the fibers to turn causing a twisting of the fibers. When the fibers twist they become stronger. As the thread if formed, the person could wind the thread onto the spindle (stick). This reduces the need for one of the hands...

The next step is two fold in nature...in the middle east the person doing the thread making would lay the fibers on the ground and then would turn the spindle with one hand and use the other hand to add fibers (a few at a time) to the thread. This only works in the threads are quite short in length. This is especially true of cotton. The only problem is that this method is inefficient. They could only do one thing at a time.

In Europe they did something differently...according to the popular saying "necessity is the mother of inventions"...what the Europeans did was that they held the fibers in their one hand and dropped the spindle allowing the spindle to spin like a yo-yo. The only drawback to this method was that as the new thread form one had to wind the formed thread on the spindle. But so what? Compared to the middle east, the spinners were more efficient. Doing the spinning like this allows one to be mobile. One could spin thread even when they were riding on a donkey! Even when they were walking.

Here's a woodcut from the 1600's showing how they could walk and spin thread at the same time:

Notice that the girl is able to hold the staff in her bodice, hold the unformed thread in one hand and allow the spindle to spin the thread. Spinning the thread this way was much easier than having to rub the threads on the outside of the thigh!

This is a very old woodcut of two women spinning.

This is a picture of a woman spinning thread using a later version of the spinning wheel. Notice that she is able to hold a larger amount of the fibers so that she would not be interrupted by having to add more fibers.

During the Middle Ages the spinning wheel was . We don't know who invented the spinning wheel, but we do know that thinventedere was an old Chinese invention that wound thread. The Chinese invention was foot powered. This by itself again was a drawback...you couldn't spin anywhere's...you had to be a place where the raw materials and the spinning wheel were kept. Initially, women were spinners as the process was thought of as being dull and monotonous. Later as things became mechanized, men took the jobs over.

The one good thing about the spinning wheel is that it sped up the process of making thread. No logger did the woman have to labor all day to produce whatever amount of thread she needed. Now she could spin in a matter of hours whatever she needed!

This is a woodcut (I believe) of a fairly ancient spinning wheel...the word "ancient" to me means that something is at least several hundred years old.

Once the thread was spun and on the staff there was one more thing that had to be done to perfect the thread so that it could be used for weaving. When the thread was being removed from the loom the thread would unwind (untwist). One of the ways to cure this is to ply the thread thus holding itself in a position. The word ply comes from the French word "plier" which means "to bend".

In different parts of the world the same thing occurred on a variety of plants. Flax is a good example. Flax would be gathered from the field and allowed to ret (rot). When the plant was fully retted, the separating of the flax fibers from the stem was made easier. The retted stems would be beaten and twisted until flax was released.

Once the fibers were separated they were processed by hackling (combing the fibers until they were all clean) the threads would all lay in one direction and joined together and then the process of weaving could begin.

Thousands of years later man would discover that not only could one use bark or flax, but also cotton and wool could be used. But that is a much later story. Other types of wild plants will also work to produce to threads: Hemp, nettle ramie, juste, sisal, esparto, maguey, yucca, elm, willow, linden...this list could go on and on...

Cotton only grew in certain parts of the world...basically the Middle east. Flax grew there as well.

Wool grew everywhere domesticated animals were. Again, in the Middle East camel hair would be picked right off the skin as it was being shed and made into thread right on the spot. The first to do this were the camel drivers who used the thread to repair things with.

Wool was a little more difficult to work with. Wool needed to be carded (carding means making the threads of wool to lie parallel to each other. But there's another reason for carding: Carding removes impurities from the wool. It removes twigs, pieces of bark, leaves, seeds that may have come lodged in the wool or cotton. With cotton, carding removes the cotton seeds which are picked out and saved for the next years planting.

Below is a picture of a small section of a cotton field

HISTORY OF WEAVING

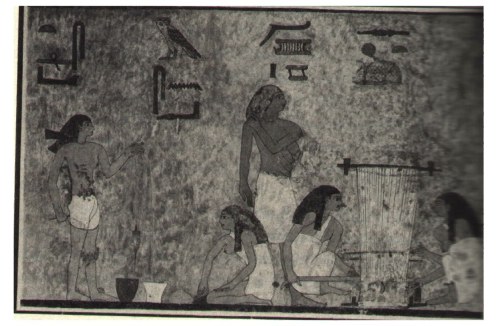

Hieroglyphic images of Egyptians using a weaving loom during the BC period

Example of a Horizontal weaving loom early Egyptian period

Example of a warp weighted loom from Greece, pre BC era.

Once the thread was produced they had to come up with a use for it! One person probably tried to hand weave by laying the threads on some sort of a surface and then weaving them together to make a piece of fabric. The only problem with this is that the threads just flopped all over probably becoming tangled into one big mess. Finally someone must have developed the idea of using a stick to hang the threads from. They had a good idea, but it wasn't quite developed yet! What someone else did changed the way that weaving forever. What they did was to hang both the top and the bottom of the thread on separate sticks! This caused the threads to be manageable...later more developments would change the method that fabric would be woven. They were going to call this thing "Thread On A Stick"...but someone else came up with a better name and the name "loom" came into being.

The earliest looms were invented somewhere's the 5th millennium BC. The simplest looms is the back strap loom or body tension loom. Even though the body strap loom is ancient it is still being used today in South and Central America and in many parts of South East Asia. On one end the warps are attached to a fixed beam or post and at the other to a breast beam held to the weaver's body by a belt or strap. The warp is held at an angle of about forty degrees to the ground, and the weaver controls the tension through the movement of his or her own body.

Very ancient in origin the next generation of the weaving industry is the warp-weighted loom. The loom was hung vertically and each weight held a specific thread. This design was started in the Middle east in Greece and has been used in Scandinavia and Iceland right up to this century. One of he problems with this design is that it took two people to operate. Here's how the warp-weighted loom worked: Two wooden uprights placed at an angle against a wall hold a horizontal beam which revolved to store the finished cloth. A set of odd-numbered warps, also weighted, hung in front. To reverse the process the warps hanging behind the shed rod were attached by loops of thread (leashes) to another stick, which enabled them to be pulled forward to form a second shed, or counter shed, in front of the other set. This device was later named a heddle, was placed between the shed stick and the finished cloth. By the year 300 AD (or so) the horizontal (ground) loom was invented.

The horizontal loom is the one loom who has been designed over the course of history. This design also uses a heddle. The warp is stretched between two beams which are held in place by four pegs hammered into the ground. The heddle is fixed and is supported several centimeters above the ground. The warps thereby raised forms one shed, while the other is formed by moving the shed rod and pulling the lower set of warps by hand to raise them above those held by the heddle. Each pass of the weft is beaten firmly with a flat stick. The loom size probably determined the length of the cloth to be woven, but the discovery of some very long pieces of linen at Egyptian burial sites indicates that the Egyptians may have used roller beams. A form of the horizontal loom is still being used today by Bedouin and other nomadic weavers of the Middle East, Pakistan and North Africa.

The next development was the two beam (vertical) loom. This is where weaving gets serious and uses a vertical lower beam that takes the place of the weights in the warp-weighted loom.

The lower beam is used as a rolling beam to hold the finished cloth in place while the weaving continues. This design first shows up in wall paintings during the 1900 BC era. The interesting is that the weavers could sit in one place and the finished cloth was rolled up on the lower beam.

The next type of loom that was developed was the treadle loom. The treadle loom was the next version of the two beam vertical loom. This design used the feet to move the shed. Therefore the hands could move the shuttle quickly. The origins of the treadle loom go back to Chinese silk weaving, which was at an advanced stage of development two to three centuries before the Christian era. It is thought to have arrived in Europe during the Middle Ages with the organized wool industry in the Low Countries and was certainly known in its fully developed form by the thirteenth century. The treadle loom is still used by hand-weavers today, and a simple treadle mechanism is a characteristic of the narrow strip looms of West Africa.

Excavations in the Tizra Valley in Hungary have found remains of several huts that date approximately 5500 BC, some of the huts were equipped with sets of clay loom weights along with the household gear. One excavation found the outlines of a vertical loom that was approximately 4 to 5 feet in width.

Later approximately 1500 BC The vertical loom was introduced, with one twist..it operated by males! In Egypt, the vertical loom replaced the horizontal loom that had been around for almost 3,000 years!

One question I had while preparing these studies into the history of quilting is how did the weavers knot the ends of the threads together so as not to cause a series of knots? Here is what I learned: The women spliced the ends together using their saliva. It seems that the human saliva contains enzymes that cause the cellulose fibers to decompose slightly into a sticky substance. While they were weaving, they would use an "upside down" type of candleholder that had the handle on the inside of the bowl. What the women would do is that as they used up the thread, they would add water to the bowl...that way they would keep their thread constantly wet without the thread jumping out of the bowl as they used it. Interesting.

I would have expected that the sheeting that was made by the Egyptians would have been stiff, thick and lousy to wear or even to sleep under. Not SO! They Egyptians were making sheeting that were 200 threads per inch. That's high quality even by today's standards. Some of the not-so-hot-modern sheeting can run as low as 100 threads per inch.

I was also struck by the fact that some of the linens that have been found in Egypt have been as large as 9 feet wide by 75 feet long. Even by today's standards that's a large sheet.

In England "fuller's clay" originated with the textile industry, in which textile workers (or fullers) cleaned raw wool by kneading it in a mixture of water and fine earth that adsorbed oil, dirt, and other contaminants from the fibers. Yep. That's how they would clean the fibers before processing for thread...they would take the wool and kneading the wool with fine earth. A dirty mess. In fact, there was a professions for they and they were called: "Fullers". The next time you meet someone whose last name is Fuller you will know what their families did "way back when".

DYEING

Until the ability to add color was developed everyone did NOT wear only white. What I found very interesting is that all over the world sheep wool came in different colors! Some sheep wool was black, some was brown, beige, etc. However for those who didn't have much colorful wool the development of the process of dyeing came about. Initially, flax was hard to dye. For some reason, the dye would not take in flax.

There are two different types of dyes. Direct dyes are the simpler to explain and its pretty much What-You-See-Is-What-You-Get. Usually direct dyes come from plants. All you have to do is to experiment with different plants until you find the exact dye color you want. Some started with the MADDER plant (this still grows in the wild on the Island of Crete)...they had to chop and simmer the root of the plant. A dark red soup will form. This will dye wool an orangey red. If you simmer the stamens of the saffron Lilly an orange broth will appear and a bright yellow dye color.

Also in Crete they used a female insect also known as kermes (from which we get the name for crimson) which contains a single drop of a gorgeous red dye.

The other type of dyes are called vat dyes. One of the best examples of dye is the woad plant. The word "woad" is so old that we know that it has been around almost as long as we have had dirt. This color is indigo blue the same for our blue jeans of today.

Many dyes had to be fermented and the work tended to be very smelly. Other dyes and cleaning operations would use stale uric acid and ammonia obtainable only by allowing urine to go stale. In Pompeii they would post a sign on an urn asking for people to donate their urine!

The people of the Middle East also used several species of sea snails to color their fabric. One of them is the murex. Each snail contained approximately one drop of the color! This color later became known as Royal Purple. As the name implies the royalty of the country passed a law that decreed that only they could wear Royal Purple. If anyone was caught with fabric with the Royal Purple they could/would be put to death.

This is especially important in Israel today. A few years ago several snails of the murex were found in the Mediterranean. The murex had been considered as an extinct species until some divers found an entire bed of them living in the "Med". All of the "Royal Blue" colors are now able to be developed once again after several thousands of years of the snails becoming extinct.

The Royal Blue color was also used extensively in the various Temples that were built in Israel.

Many dyestuffs will not be directly be absorbed a by a fiber, so mordant's (from the French word mordre (means "to bite") or fixing agents are used which combine with dye and fiber to make the color insoluble. Madder was an important was an important dye stuff that could not be made colorfast without the addition of a mordant. The mordant (or a variety mordants) is applied to the cloth in the same ways to a resist, then the fabric is submerged in the madder dye bath; but where indigo resist dyeing presents the pattern in negative (white on a blue ground), a mordanted madder design appears positive (red on a white background). Different mordants will produce a whole range of tones and shades within a group of colors.

"Love Spell to Compel a Woman"

Hail to you, O Re-Horakhte, Father of the Gods!

Hail to you, O Seven Hathors, who are adorned

with strings of red thread!

Source: Professor Robert Ritner, University of

Chicago Oriental Institute

SOCIAL IMPLICATIONS OF CLOTHING

Throughout the world clothing has been used to designate both the social standing in the local/tribal social order and the sex of the wearer. In the Oceanic area of the world the quality and the decoration of clothing marked the social rank of the wearer.

In the later years of China embroidery on official robes functioned as a means of communicating status and authority within the court hierarchy.

South East Asian textiles not only defined the status of the individual, but the layout of patterns may also denote family lineage and clan identity. Unfortunately designs tend to have a specific meaning for a particular ethnic group alone and can after some use become "lost" to outsiders and to the members of that clan or group. A good example is the use of Javanese Batiks the motifs originally had a separate meaning, and the wearer was expected to select a cloth appropriate for the occasion. Even the traditional meanings have been lost, the original designs are still being used today.

Clothing is not merely used to cover ones body out of modesty. In the history of our world textiles have been worn to display the status and social rank of an individual. That's why the leader of the country wears more expensive clothing than a sheepherder in Africa (to make an example). That's why the Pharaoh of Egypt worn more ornate clothing than the blind beggar.

In the Byzantine age emperors silk was a powerful political tool. A foreign government might be snubbed by the Emperor while another visiting dignitary might be rewarded with precious silk.

The Inca emperors demanded that their subjects to make cloth as a tribute which the emperors gave to their army or were used as gifts.

In many societies textiles have played a vital role in the social, economic, and religious life of the community. They are essential accouterments in all major life-cycle ceremonies as births, weddings, funerals, when they are bestowed as gifts, exchanged, burned, buried, or passed on to the next generation as the substance of a dynasty.

Death and mourning have involved as many rituals using cloth. Some cultures have seen cloth as, literally, a thread binding the generations. The Grand parents have oft taught their Grand Children the art of needlework. Thus freeing both of the parents to work on the farm. Thus, the cycle of needlework was handed from one generation to the next directly and usually without loss of content. Sad to say, in our modern age of materialism and the slow degradation of the family structure this type of education is being loss in droves. Never again will the Matriarch of the household sit down with the children (especially the females) and teach the delicate art of the almost countless types of stitches. Never again will the children be able to be taught by "G'ama'" as she helps the child learn not only how to sew, but also how to spell by working on samplers!

Gone forever is the ability of the person who is the crafter (be it textile, wood, etc.) to turn out their goods on a spiritual basis. The introduction of a capitalist production system in so many parts of the world during the past two centuries has radically reordered the role of textiles in society. Schneider and Weiner in Cloth and Human Experience suggest that the capitalist production system eliminates the opportunity for textile producers (spinners, weavers, dyers, and so on) to infuse the goods they produce with spiritual value. The second effect is that in producing endless variation and rapid turnover capitalism has encouraged the growth of the modern fashion in a system where dress has become the predominant means of expression.

We can't leave this section without examining at some length the role of the male and the female in the making of textiles. Initially it may have been the female who worked the first thread for the construction for a fishing weir. Or, it may have been a male who developed the first rope to be used as a noose to catch deer. No one knows for certain.

We DO know some things however. We know that women played a far larger role than men in making textiles. Schneider and Weiner have the idea that where women are the main producers of textiles and control their distribution too they wield considerable power in social and political life, under capitalism their contribution has been devalued. In Roman societies, women were able to setup and manage their own textile businesses and arranging their textiles to be traded over vast areas.

In Africa there are instances where men being the predominant producers of textiles. But there are also examples where men and women worked together who produce both woven and dyed textiles and embroidery.

CONDITIONS IN THE TEXTILE MILLS

By 1824 the working conditions for British textile workers had severely degraded. Here's an actual report from the writings of William Cobbett: "In the cotton spinning work these creatures are kept, 14 hours each day, locked up summer and winter, in a heat of EIGHTY TO EIGHTY FOUR DEGREES". Cobbett continues to state that at this temperature in the fields both horses and men dropped dead; 'they have no cool room to retreat to...the door of the place wherein they worked, is locked except half an hour at tea time; the work people are not allowed to send for water to drink in the hot weather'.

Cobbett also lists the various fines that the factories could impose on a person: "Any spinner found with his window open 1s (1 Shilling), any spinner found washing himself 1s. Any spinner leaving his oil can out of its place 6d. Any spinner heard whistling 1s. Any two spinners found together in the necessary, each man 1s."

"Each mans pay has to be laid out at a shop. That shop is generally the masters, who also owned the cottages or cellars in which the workmen must live."

Not only is there research that shows the conditions for the working adults, there are also examples of what this work had on children. The work of attending the machinery of throwing mills was neither difficult or arduous, and was well suited to the children of the poor. Because there were so many poor (in our day they would have been referred to as the "working poor"), the powers that be saw the children as pretty much an endless source of cheap labor. By 1813 George Courtauld was recruiting parish children from workhouses to be bound apprentices. "I had my choice of upwards of 50 girls of different ages and accepted all but one that were within the age of 10 and 13...I really expect and earnestly hope that by continued care and attention my establishment of apprentices will prove a nursery of respectable young women fitted for any of the humble walks of life." Courtauld's proposed to supervise these child workers with persons who would maintain "perfect silence except the perfect singing of hymns which we find a useful relaxation and a help to industry, attention and orderly conduct". Courtaulds were among the best when it came to educating, welfare and help for their child employees. One could ask the question regarding Samuel Courtauld who drew an average annual income of 46,000 pounds Sterling, his total income with all perks, etc. approached 70,000 pounds Sterling while the amount he paid his foreman dyer was 62 pounds Sterling 10 Shillings per annum. One of his power loom operators averages 15 pounds Sterling annually!

The American textile worker faired better than their British cousins. Harriet Farley is one example. Harriet Farley was born in 1813 in Claremont, New Hampshire.

In 1837 she made her way to Lowell and obtained a position in a textile mill. She eagerly threw herself into the lectures and other activities that promoted culture among the female workers of the Lowell mills, and in December 1840 she attracted some attention when her reply to Orestes Brownson's criticisms of the working conditions in the mills was published by the Lowell Offering. The Lowell Offering, a magazine written by and for the "mill girls," changed ownership in October 1842, and Farley was invited to become editor. Harriet Curtis, another mill worker, became her coeditor in 1843.

Under Farley's direction the Offering was a literary magazine of the most conventional sort, publishing moral and inspirational pieces that were meant to demonstrate the intelligence and refinement of the working girls and women of Lowell. The magazine attracted attention as far away as Great Britain, where an anthology of Offering pieces was published in 1844. However, the respectability of the magazine foundered in the rising tide of labor unrest of the mid-1840s, and by explicitly refusing to discuss the issues of hours, wages, and working conditions, the Offering lost its appeal to its own audience. Criticism of the magazine, spearheaded by Sarah Bagley, led to its demise in December 1845.

Harriet died in 1907.

Workers who worked at the mills of Francis Cabot Lowell were fortunate. The working conditions in his mill and the workers' housing that he built were exemplary for the period.

Lowell was begun with the high-minded purpose of proving that the wretched working conditions in English factories were not a necessary byproduct of industrialization. The original workers at Lowell were New England girls of "good family." They were set up in carefully supervised boardinghouses in the company town and were provided with a library and a variety of "uplifting" activities, including religious instruction. In the late 1840s, however, life at Lowell began to change. Wages were lowered, the workload and hours were increased, and the living quarters deteriorated. The change was in part due to rigorous competition from less idealistic producers. In addition, after 1846 cheap immigrant labor became increasingly available, especially from Ireland. Meanwhile, the relationship between owners and operatives became less paternalistic.

The following set of regulations was laid down by one of the factories for its employees in 1848.

Regulations to be observed by all persons employed...

The overseers are to be always in their rooms at the starting of the mill, and not absent unnecessarily during working hours. They are to see that all those employed in their rooms are in their places in due season and keep a correct account of their time and work. They may grant leave of absence to those employed under them when they have spare hands to supply their places, and not otherwise, except in cases of absolute necessity.

All persons in the employ of the Hamilton Manufacturing Company are to observe the regulations of the room where they are employed. They are not to be absent from their work without the consent of the overseer, except in cases of sickness, and then they are to send him word of the cause of their absence. They are to board in one of the houses of the company and give information at the counting room: Where they board, when they begin, or whenever they change their boarding place; and are to observe the regulations of their boardinghouse.

Those intending to leave the employment of the company are to give at least two weeks' notice thereof to their overseer.

All persons entering into the employment of the company are considered as engaged for twelve months, and those who leave sooner or do not comply with all these regulations will not be entitled to a regular discharge.

The company will not employ anyone who is habitually absent from public worship on the Sabbath or known to be guilty of immorality. Thus, Orthodox Jewish females were not allowed to work at the mills.

A physician will attend once in every month at the counting room to vaccinate all who may need it, free of expense.

Anyone who shall take from the mills or the yard any yarn, cloth, or other article belonging to the company will be considered guilty of stealing and be liable to prosecution.

Payment will be made monthly, including board and wages. The accounts will be made up to the last Saturday but one in every month and paid in the course of the following week.

These regulations are considered part of the contract with which all persons entering into the employment of the Hamilton Manufacturing Company engage to comply.