History of Feedsacks

History of Feedsacks

The samples of feed sacks that we have on our web site all come from my own extensive collection of feed sacks. I attempted NOT to make the samples too small so that all of the detail and designs could be seen very clearly.

If you have a question as to the authenticity of any feed sack type of quilt, compare what your sample is to what we have in our collection. Hopefully you will find some answers to your questions.

HISTORY OF FEED SACKS

FEED Sacks' short history...

The use of feed sacks for the transportation of animal feeds, fertilizers, etc. came as a direct result of the rising cost of the manufacturing of oak barrels. At least that's my theory.

One of the many problems with the construction of the old fashioned oak barrels was that they were VERY labor intensive to build. They called for well trained people who knew by instinct just how to build an oak barrel. There were many steps in the process of building an oak barrel:

Design was paramount.

The oak wood had to be kept on hand so that the orders could be filled as rapidly as possible. The wood for the staves and headers had to air dry for at least a year! After the air drying they were kiln dried for 10 to 20 days before being planed to the right size.

The staves had to be made...just so. The barrel would fit together with the ring that holds the barrel in place. They couldn't just go down to their local lumber yard and place and order for so many staves. A crucial operation is jointing of the edges of the staves and giving them the proper bilge (middle bulge) so that the joints will be tight and the circumference uniform. The bulge allows the barrel to be stronger to internal pressure.

The most complex part of the operation is called "raising the barrel". Staves are set vertically into a head truss ring, and a temporary hoop is placed over the other end. The staves then pass

through a steam tunnel to allow the staves to bend for drawing into final shape and then dried again. A machine called a crozer trims the ends of the staves and cuts the croze, the groove near the end of the stave where the head pieces fit. The temporary end rings are pulled off, the head pieces fitted, and permanent head hoops put in place. The temporary bilge hoops are removed, and the rest of the permanent hoops are put on. Thus the barrel is made.

See how difficult it is?

Remember that this is the time before modern inventions. Before the time of the Industrial Revolution and more importantly...before the time of Henry Ford. Before the design and construction of the first assembly line.

Another problem with the oak barrels is that sometimes they would leak! Imagine filling a large barrel with animal feed and then as it being transported to the wholesaler...it would break open and everything would spill out! This was especially disastrous if you had filled the barrel with a liquid...

Quite often the same person made the entire barrel. He who started it, finished it. It would take days to construct merely one barrel. Perhaps they would only build one or two barrels, maybe 3 a week.

The fabric industry wasn't much better. Everything had to be done by hand...until..John Kay's flying shuttle in 1733, which allowed the weaving of larger widths of cloth and significantly increased weaving speed; (2) Edmund Cartwright's power loom in 1785, which sped weaving speed; (3) James Hargreaves' spinning jenny in 1764; (4) Richard Arkwright's water frame in 1769; and (5) Samuel Crompton's spinning mule in 1779.

The last three inventions improved the speed and quality of thread-spinning operations. Thus cutting the cost of manufacturing of fabric. A sixth invention, the steam engine, perfected by James Watt, was the key to further rapid development. After making major improvements in steam engine design in 1765, Watt continued his development and refinement of the engine until, in 1785, he successfully used one in a cotton mill. By 1793 the invention of the cotton gin leads to rise of cotton industry and mills in the northeast of the United States.

Somewhere's along the path of life, no one is certain just when it was, the two came together in feed sacks!

The cylinder printing press meant that fabric could be printed for mere cents on the dollar per roll instead of the labor intensive hand stamping. An interesting note is that a color print of fabric would have taken 15 hours to complete with wood blocks could be done by cylinder printing in less than 90 seconds! The direct result is that the fabric that had cost about 22 cents per yard in 1820, cost 10 cents by the 1850s, dropped to 5 cents per yard by the late 1870s. Thus, it was the lowering of the price of fabric that allowed for new forms of use of fabric.

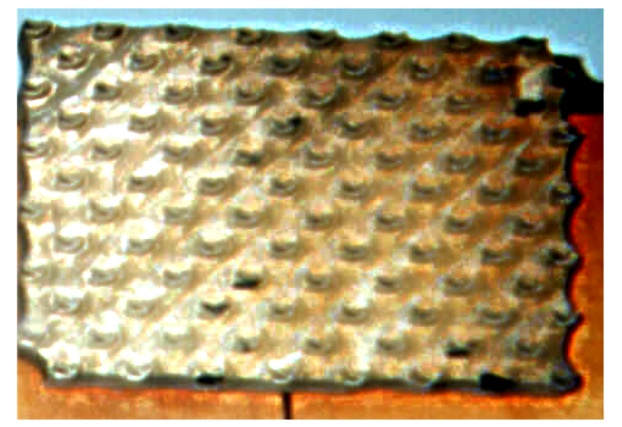

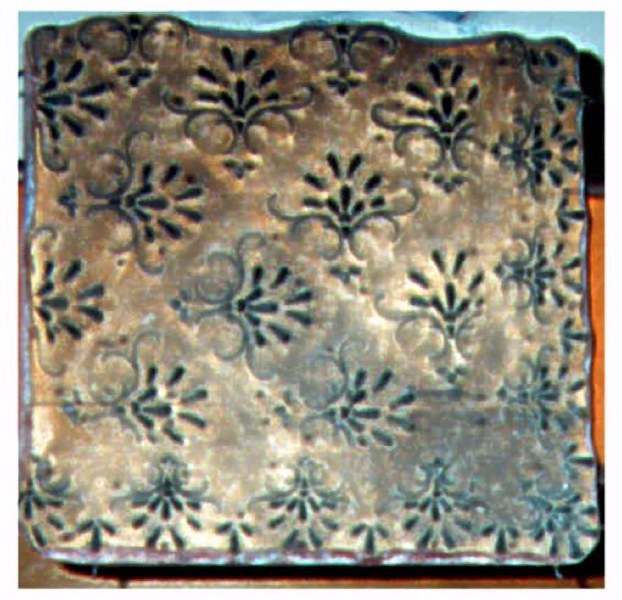

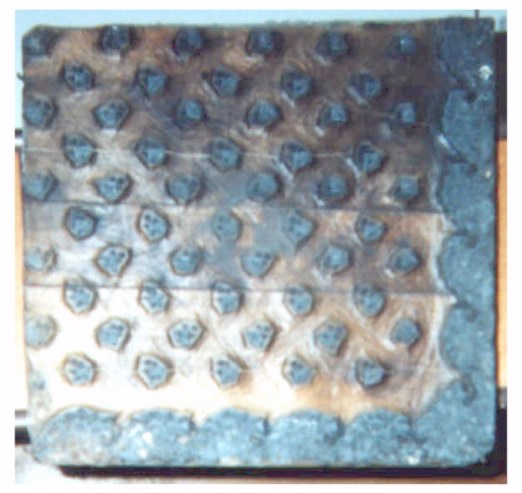

When printing fabric they would stamp the fabric with a large wooden square that had a handle. Once the pattern was placed on the fabric, the person doing the printing would hit the pattern with a wooden mallet. That would make certain that the print was evenly spread on the fabric. On the fabric print patterns were "registration marks" that allowed the printer to evenly match his last print with the next so that the print would be even and not overlapping. Sometimes the designers of the fabric pattern might add copper around the sides to add some extra borders. Sometimes they might use felt in between the designs on the patterns.

The fabric pattern which would be a design usually constructed out of metal covered with the color that they wanted to print. This is a very tedious job. Many times the same roll of fabric would have to be restamped over and over again with a different color. EXTREMELY labor intensive.

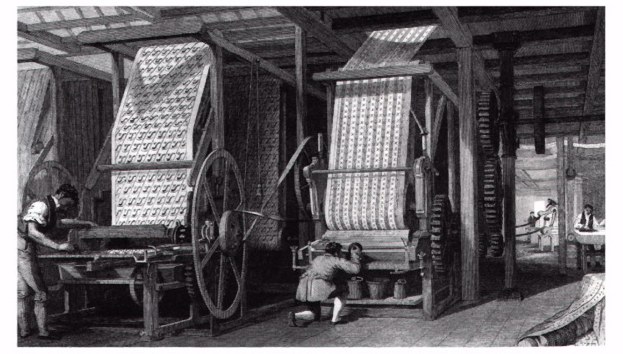

Early example of the art of fabric printing. Notice that the two women on the right are doing "penciling" (that is where additional colors are added to the fabric by using colored pencils. This print dates to 1774.

Later cylinder printing became a standard thus dropping the cost of production of fabric from dollars per yard to a mere nickel per yard by the end of the 1800's.

Eventually, a design change and the moveable printing press would be invented.

The fabric printing press meant that the process of stamping the fabric would now be pretty much automated...at least one press could replace perhaps 100 workers. This in turn caused many people to be laid off...financial hardships came about.

Roller printing is first used to make patterned fabric in England (1783). They can produce in 4 minutes the same amount of fabric it would take 6 hours to do by hand.

In 1814 the power loom is installed in Waltham, MA. First American factory production of cloth and thread begins.

Somewhere along the line some one decided to invent cloth bags. A bag manufacturer came up with a design for a bag that could hold animal feeds. The one major sticking point is that there was no way to be able to sew the edges so that the fabric would not split apart. That would happen in 1860...

The year 1851 the first sewing machine was patented.

By 1854 "Stitching machines" (that's what they called sewing machines back then) were offered for home use.

In 1860 a sewing machine with the modern lock stitch was developed. The lock stitch is the SAME stitch that we still find on large bags of dog food. The lock stitch allowed the threads to become stronger and withstand the extra force of the items within. An ordinary stitch would allow the seams to separate and spill the goods on the ground. The lock stitch held the 3 sides of the fabric together with breaking the fabric.

By 1890 feed sacks are introduced with printed fabrics. Again some where along the road one of the sack manufacturers decided to come out with printed fabric. The idea was so novel that others copied the concept. BUT why were fabrics printed on the side of feed sacks? That answer is a simple one! To create product loyalty. One method to create product loyalty is to create a product that creates a demand. The ladies discovered that there was so many uses for feed sack fabric that the list was almost endless!

Quite often the fabric was used for curtains, drapes, table cloths, dish cloths, place mats etc.

This spring we discovered some additional uses of feed sack fabric: Clothing. We found a beautiful old fashioned bonnet that some one wore. We also found several dresses. I asked an elderly lady that I had met in a store just how they would sew the fabric together to make larger pieces of fabric. Here's her answer: "Why, we would just sew enough of the material together until you had enough to make something out of!"

Sometimes even the fabric was used for underwear. Even for men...imagine making a pair of "drawers" and having to look for fabric with a masculine motif and not having any!